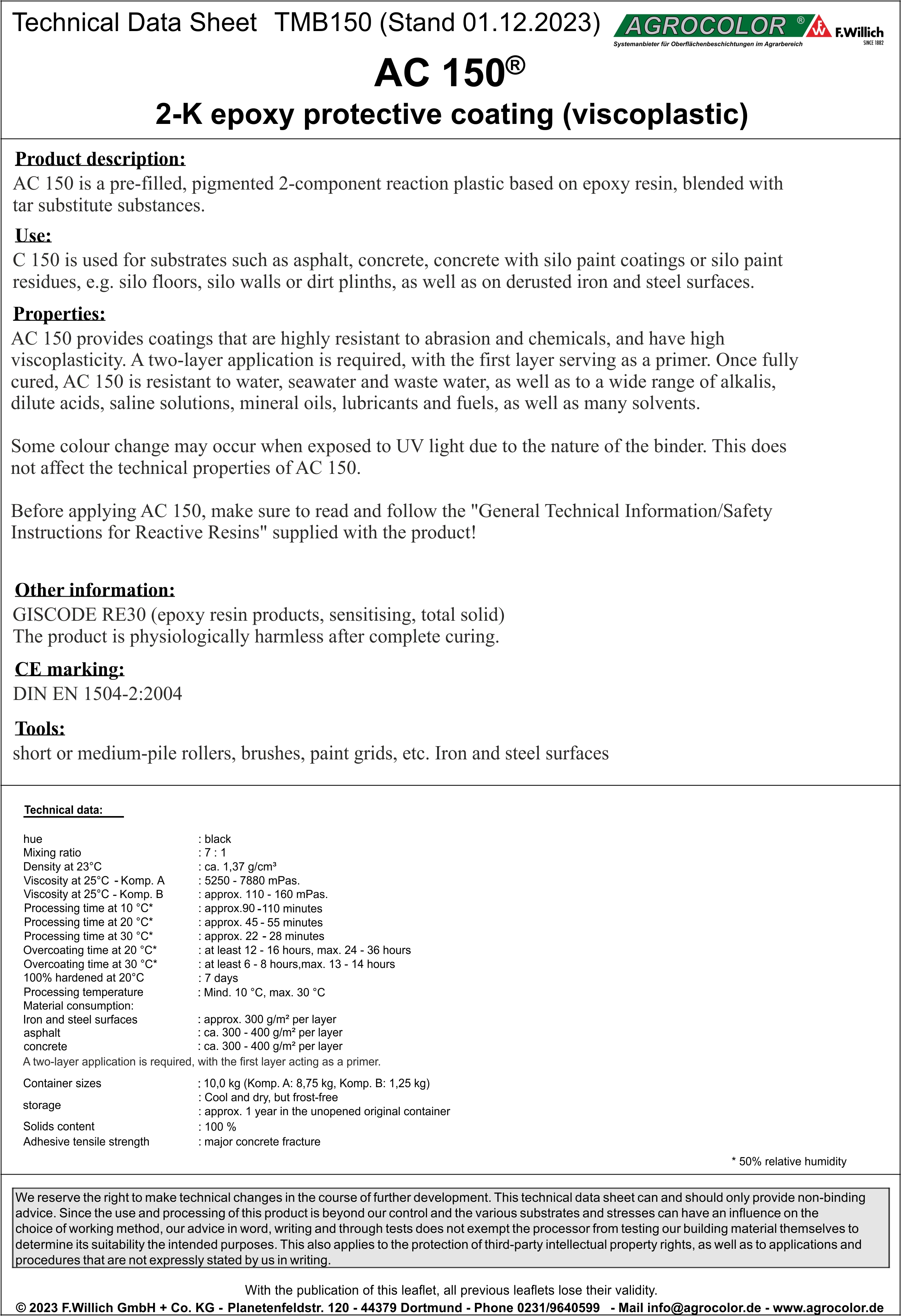

2-K epoxy protective coating (viscoplastic)

AAC 150 is a pigmented, pre-filled, two-component reactive plastic based on epoxy resin, modified with tar substitutes. AC 150 is used on substrates such as asphalt, concrete, concrete with silo coatings or coating residues (e.g. silage pit floors, silo walls, splash zones), as well as on derusted iron and steel surfaces. AC 150 produces coatings characterized by high chemical resistance, excellent abrasion resistance, and tough-elastic properties. A two-coat application is required, with the first layer serving as the primer. Once cured, AC 150 is resistant to water, seawater, and wastewater, as well as to many alkalis, diluted acids, saline solutions, mineral oils, lubricants, fuels, and various solvents. Due to the binder, slight color variation may occur with UV exposure. The technical performance of AC 150 remains unaffected. Before applying AC 150, be sure to read and follow the accompanying “General Technical Notes / Safety Instructions for Reactive Resins.”

- solvent-free

- emission-free

- physiologically harmless after complete hardening

Container size:

- 10 kg

Surfaces:

Concrete

Concrete Asphalt

Asphalt Tiles

Tiles Ferrous metals (derusted)

Ferrous metals (derusted) Screed

Screed Bitumen

Bitumen

Cement plaster

Cement plaster other metals

other metals Exposed concrete

Exposed concrete Sand-lime brick

Sand-lime brick Glass

Glass Sheetrock

Sheetrock

Tools:

short or medium-pile rollers, brushes, paint grids, etc. Iron and steel surfaces

![]()

![]()

Other information:

GISCODE RE30 (epoxy resin products, sensitising, total solid) The product is physiologically harmless after complete curing.

Application instructions

When applying reactive polymers, the temperature of the surface is crucial, in addition to the ambient temperature. Chemical reactions generally slow down at low temperatures; this also extends the application, recoatability, walkability and curing times. At the same time, the higher viscosity leads to an increase in consumption. At high temperatures, the chemical reactions are accelerated, meaning that the above-mentioned times are shortened accordingly. For the reactive polymer to cure completely, the average temperature of the surface you are applying it to must be above the minimum temperature. For more detailed application instructions, please refer to the technical data sheet and the sheet on reactive resins / application instructions.