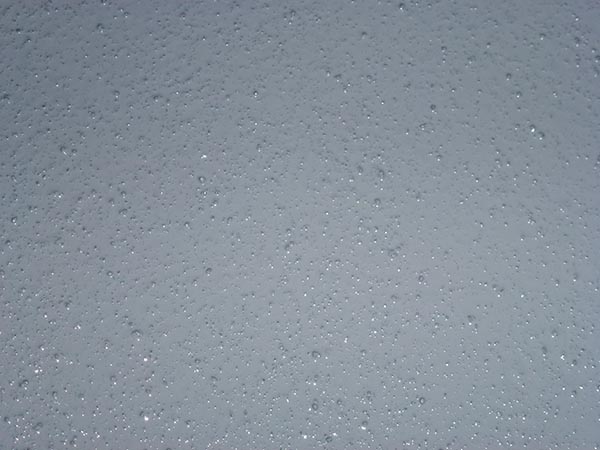

2-component epoxy top sealer, slip-resistant

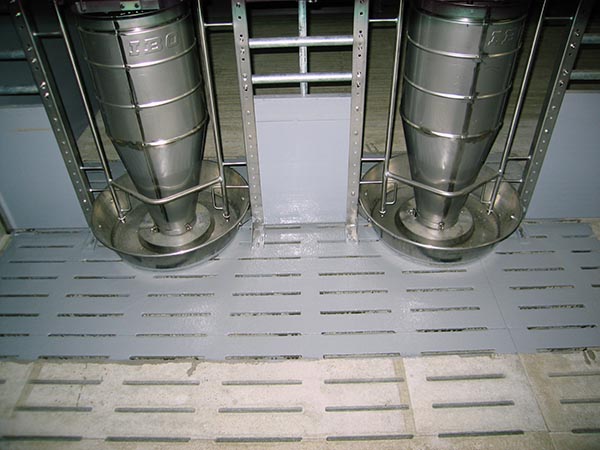

AC 130 R is a slip-resistant sealing and coating material for cement-based substrates such as concrete and cement screeds, as well as for reactive resin-bound substrates—preferably on floor surfaces subject to mechanical and chemical stress such as silo slabs, livestock resting areas, milk rooms, adjacent milking facilities, as well as warehouses and workshops.As a top sealer, AC 130 R is particularly used over AC 110 epoxy primer, AC 160 universal filler, or AC 192 repair mortar, as this further enhances mechanical and chemical resistance while producing a slip-resistant surface.

- Solvent-free

- Emission-free

- Physiologically harmless

Container size: 4,5 kg

Color: ca. RAL 7046

Surfaces:

Concrete

Concrete Asphalt

Asphalt Tiles

Tiles Ferrous metals

Ferrous metals Screed

Screed Bitumen

Bitumen Reactive resin bonded substrate

Reactive resin bonded substrate

Wood

Wood Other metals

Other metals exposed concrete

exposed concrete Laminate/PVC

Laminate/PVC Glass

Glass Drywall

Drywall

Tools:

![]()

![]()

![]()

Application instructions

When applying reactive polymers, the temperature of the surface is crucial, in addition to the ambient temperature. Chemical reactions generally slow down at low temperatures; this also extends the application, recoatability, walkability and curing times. At the same time, the higher viscosity leads to an increase in consumption. At high temperatures, the chemical reactions are accelerated, meaning that the above-mentioned times are shortened accordingly. For the reactive polymer to cure completely, the average temperature of the surface you are applying it to must be above the minimum temperature. For more detailed application instructions, please refer to the technical data sheet and the sheet on reactive resins / application instructions.